I have been collecting images of vehicle tyre tracks from Byway 745 for some time, building up a series of mono prints made by lying thin paper directly into muddy ruts. Once the mud is dry the image becomes rather faint and indecipherable, so I’ve been puzzling over how to make something stronger, and also longer, that will read, at a glance, as a tyre track. Screen printing is the process I’ve been using, making several technical steps from the original mono print to arrive at the solution.

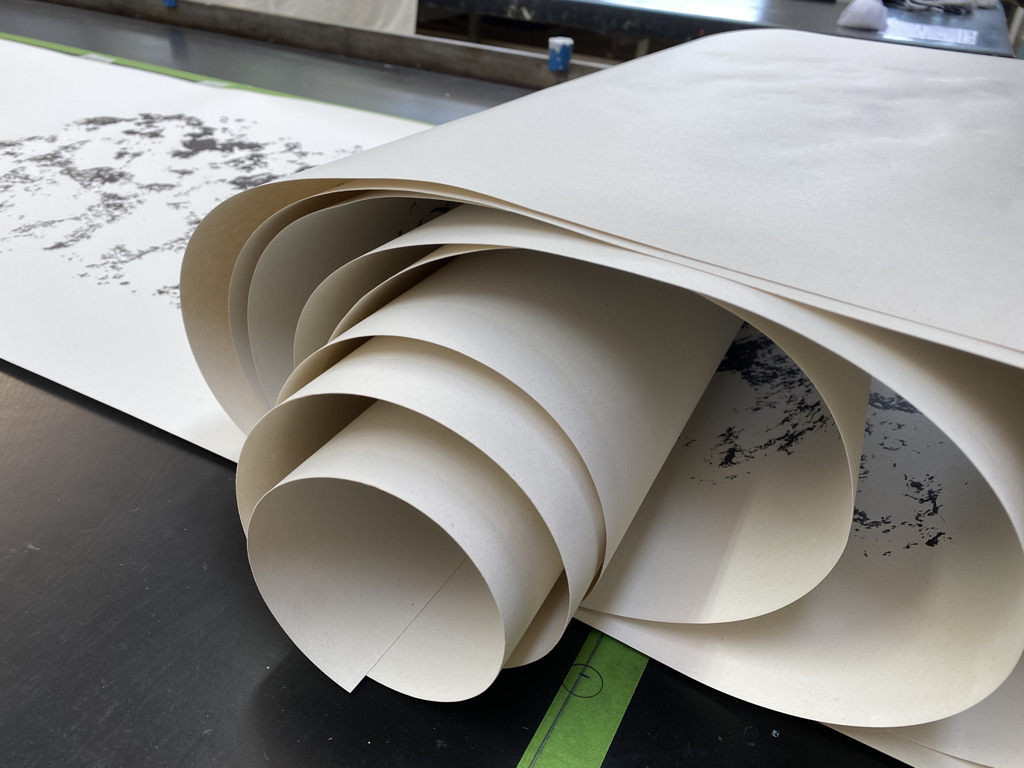

The plan was to make a repeat of the original image so that it could be printed on really long paper. The paper in mind was wallpaper lining paper, a material already used to make long drawings and frottages. This is not a direct print of the tyre track in the way that Robert Rauschenberg’s Automobile Tire Print of 1953 is, in which John Cage drove his car over the paper, but more of a simulation from a direct starting point.

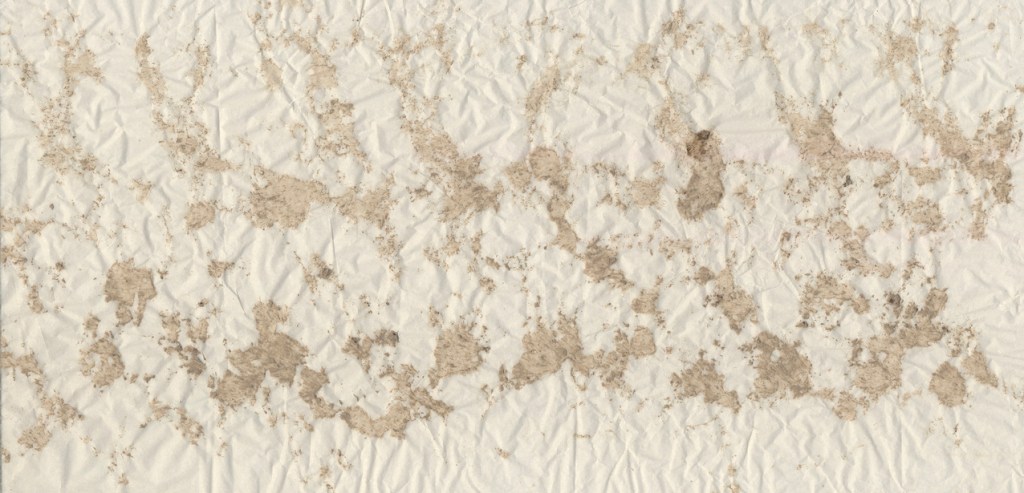

Liz Clifford. Scan of mud mono print – tyre track.

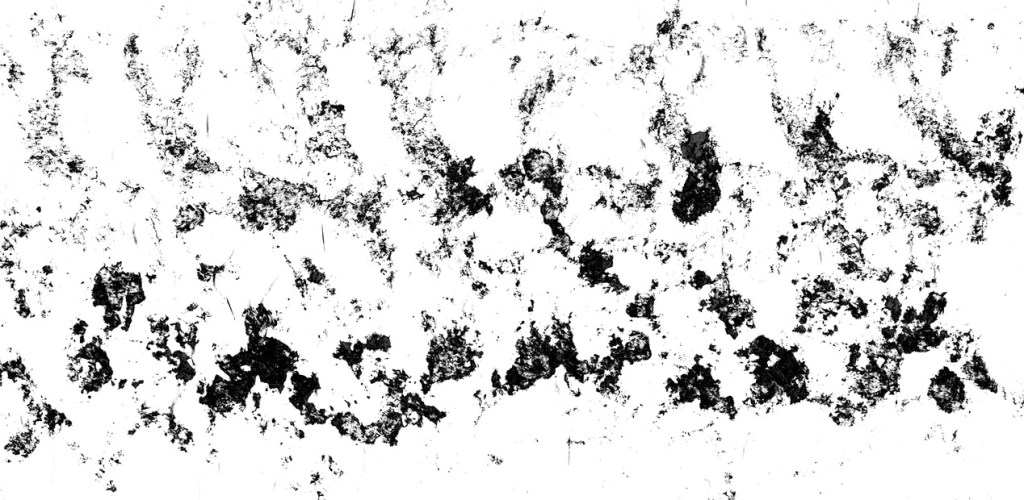

Scan converted to B & W

The first step in the process was to work on the scan in Photoshop to create a black and white image suitable for making a photo screen. This involved converting the image to greyscale, exaggerating the contrast and then making a bitmap with specific halftone screen settings for the mesh size to be used. In addition, the repeat needed to be worked out so that it would appear seamless and registration marks were needed on the positive so that this could be achieved. Luckily, I had access to excellent technical help in both Fine Art and Textiles departments at UCA, Farnham. It was the textiles department that had the space and equipment I needed to print 9m lengths in one go, as well as the method for infinite repeats.

The key to the success it this way of working is definitely in the preparation. From the original image right through to setting up the printing table. It doesn’t pay to rush or skip any of the stages. Once the screen was ready, ink mixed up and paper on standby, the table needed preparing so that the repeat would work as planned. The positive that was used to create the screen is then used to mark out the table to estimate alignment markers for the paper and the stops for each positioning of the screen.

The stops are fixed to the bar that runs down the length of the table and are numbered. The screen has a bracket that rests against one side of each stop every time you print and has two spacer bolts that ensure it is always the same distance from the bar. You print odd numbers first and then even numbers to allow the ink to dry before laying the screen over it. It was only possible to print four times before needing to clean the screen, or risk the ink drying and clogging up the mesh. An A1 size screen is a two person job as the squeegee is an arm’s span. One person holds the screen steady and helps lift it clear of the paper and into the next position.

I have around 20 metres of tyre track wallpaper to use in my work, which is really exciting. There is so much that I can afford to take risks with it, knowing that I now also have the skills to make more.

Such a process with wonderful results

LikeLike

Looks great

LikeLiked by 1 person